Machines

External cylindrical grinding machines are used for grinding cylinders and surfaces on the outer diameter of cylindrical parts.

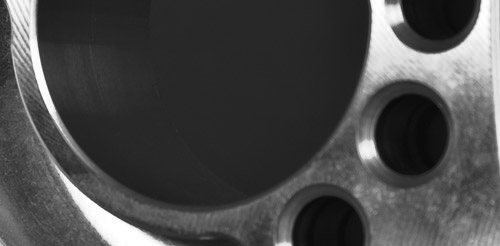

Internal cylindrical grinding machines are used for grinding holes or surfaces on the inside diameter of cylindrical parts and often they are equipped with different swing-in spindles.

Meanwhile, there are also external and internal cylindrical grinding machines (orbital or pendulum stroke grinding machines) by means of which you can grind “noncircular”.

A special form are machine tools for centreless external cylindrical grinding. Here, the workpiece is not clamped between headstock and tailstock, but it is guided between grinding wheel and regulating wheel and held from below by means of rail.

Cylindrical grinding machines are always used where workpiece machining with lathe is difficult or impossible.

Ground centers are required for minimizing defects of form and positional errors between the centers and the shoulders to be ground. For this purpose, center grinding machines[1] zur Verfügung.

There are external and internal cylindrical grinding machines for machining outer and inner contours of cylindrical workpieces or surfaces.